Indexing Milling Fixture Horizontal & Vertical (With Chuck & Tail Stock) , Code No. U1335

- Sturdy & accurately made machine vices from graded casting.

- Fine acme thread screw.

- Jaws are made of special steel properly hardened, fixed jaw is provided with vertical & horizontal ‘V’ groove to hold the round job firmly.

- Quick alignment to machines through longitudinal slot provided in base & body.

- Crank handle is made of unbreakable steel provided with a spring loaded mechanism providing positive grip.

- Body is provided with water channel.

- Depth of jaws is more to hold heavy jobs.

Unique Precision Universal Tilting Table – Code No.U 1332

- Precision Universal Tilting Table, Heavy duty closed grain Cast Iron body.

- Accurately Machined T-Slots.

- Ideal for 3 axis jobs on Milling, Drilling, Grinding, Shaping and Jig Boaring, 3 axis movement allows table to be adjusted at any angle.

Unique Precision Self Centring Vice -Swivel Base – Code No. U 1314S

- Casting close grained high tensile Seasoned Cast Iron.

- Screw spindle made of tool steel cut spindle thread for firm gripping and smooth operation.

- Fully Hardened and ground tool Steel Jaws.

- The 360° Swivel Base, graduated in 1° increment.

- Quick alignment on the Machine table through longitudinal slot provided in the base.

- Accurate centring of jobs automatically

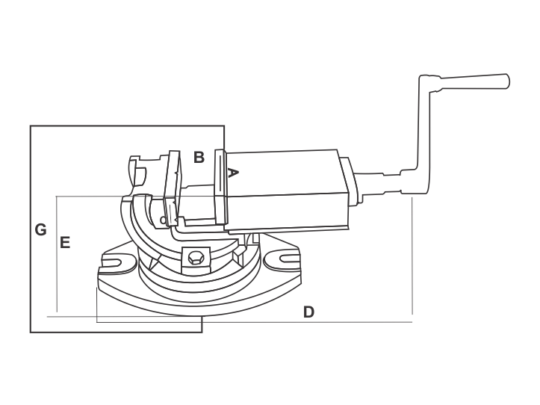

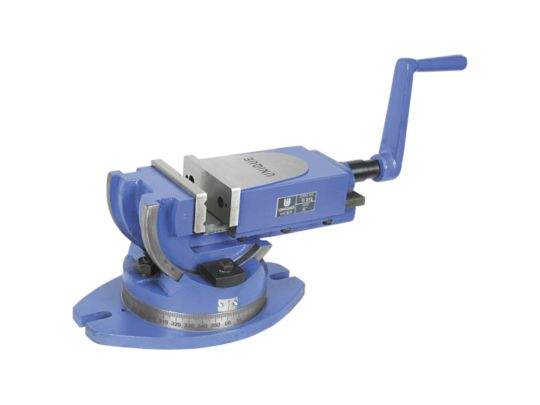

Precision Machine Vice , Swivel Base Code No. U329

- Unique design for high accuracy.

- Minimum vibration.

- Low height with rigidity

Features

- Fitted with Thrust Bearing for Smooth Movement.

- Positive locking to withstand heavy loads.

- Horizontal Swivel movement 360º.

- Vertical swivel movement 90º.

- Fine acme thread screw made out of special steel.

- Quick alignment to machine tables using a longitudinal slot.

- One vertical Two horizontal ‘V’ grooves are provided in hardened and ground jaws .

- Crank Handle is made of unbreakable steel provided with a spring loaded mechanism.

- Supplied with Stopper for Fast Production.

ALSO AVAILABLE IN DUCTILE IRON (UNBREAKABLE BODY)

Specifications

| Sizes in Inches | 2 | 3 | 4 | 5 | 6 | 8 | |

|---|---|---|---|---|---|---|---|

| A | Width of jaws in mm | 50 | 80 | 100 | 125 | 150 | 200 |

| B | Opening of jaws in mm | 50 | 75 | 100 | 125 | 150 | 200 |

| C | Depth of jaws in mm | 25 | 38 | 42 | 50 | 50 | 60 |

| D | Length overall in mm | 210 | 285 | 370 | 450 | 540 | 640 |

| E | Height overall in mm | 95 | 225 | 160 | 170 | 195 | 220 |

| G | Width overall in mm | 105 | 140 | 170 | 228 | 236 | 280 |

| Tenon Slot Size in mm | 16 | 16 | 16 | 20 | 20 | 20 | |

| Weight (Approx) in kgs. | 4 | 8.5 | 18 | 30 | 44 | 73 |